MECHANICAL

DESIGNS

FROM INDIVIDUAL PARTS

TO ASSEMBLY

Fine mechanics competence centre

For fuzes with the precision movement of a clock mechanism

Whether fine-mechanical individual parts from the injection moulding process, mechanical fuzes and fuze components, mechanical safety and arming devices or entire micromechanical components: JUNGHANS microtec, our competence centre for precision mechanics at the Dunningen-Seedorf site (Germany), combines decades of experience with the latest development and manufacturing facilities for high-quality products with outstanding precision.

Strong concepts: development from simulation to prototype

More than 15 engineers and technicians in the development department are responsible for the creation of new products. With state-of-the-art design, calculation and simulation tools, we develop innovative solutions for our customers that meet the highest requirements. Combining our employees’ long-standing know-how, and efficient manufacturing technologies with modern machinery, we deliver products with consistently outstanding reliability. From the first idea to the serial product, our engineers receive support from our broad network of specialists in technology, mould construction and production.

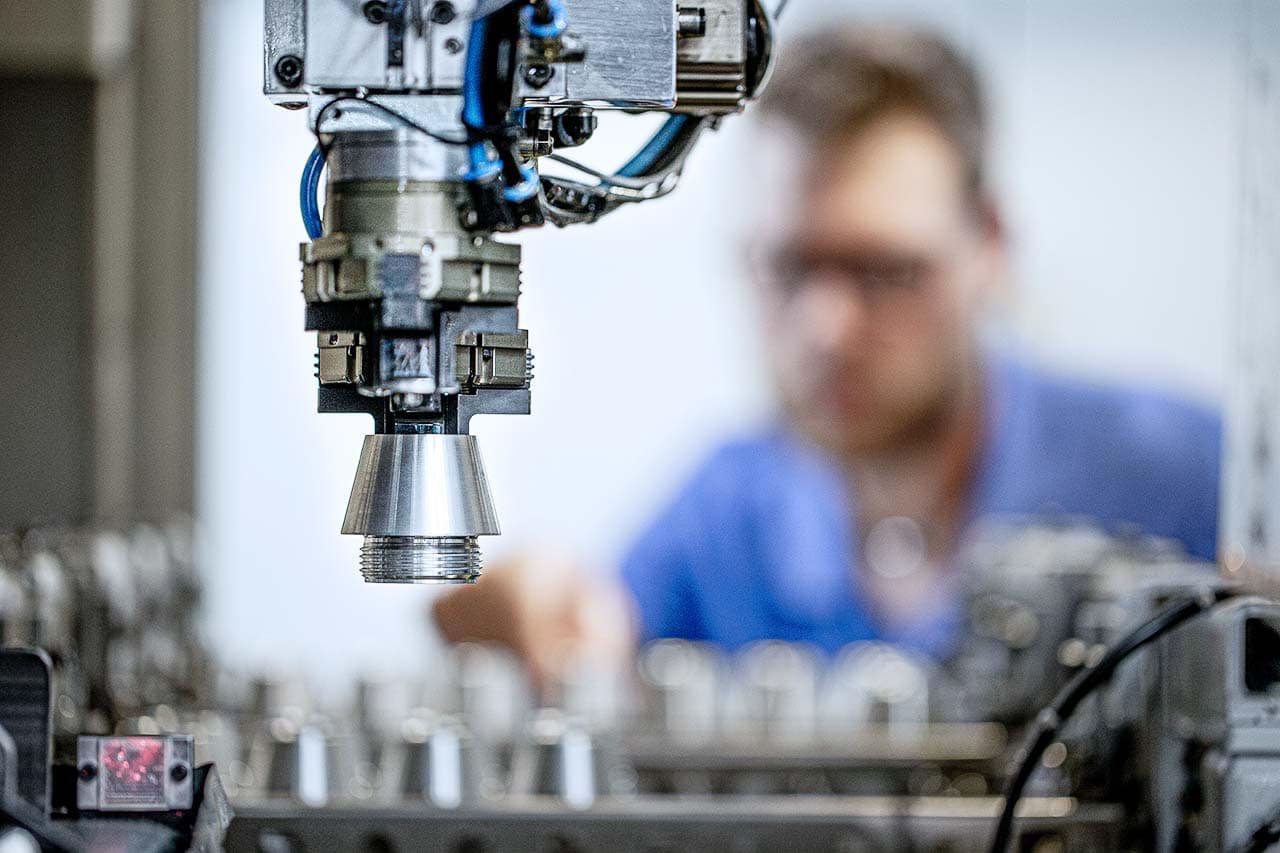

Maximum efficiency: manufacturing with state-of-the-art production equipment and tools

With continuous investments in our competence centre for precision mechanics, we ensure efficient production of fuzes and precision parts that offer an optimum price/performance ratio in addition to the highest quality. What’s more, our customers benefit from the unique expertise of our manufacturing staff in assembling, testing and integrating fuzes and safety and arming devices. Production takes place completely in-house with machining by turning, CNC processing, finishing, heat treatment and fine cutting as well as with the production of plastic and metal casting tools. In this way, we remain flexible and are able to produce high quantities of up to several hundred thousand fuzes per year.

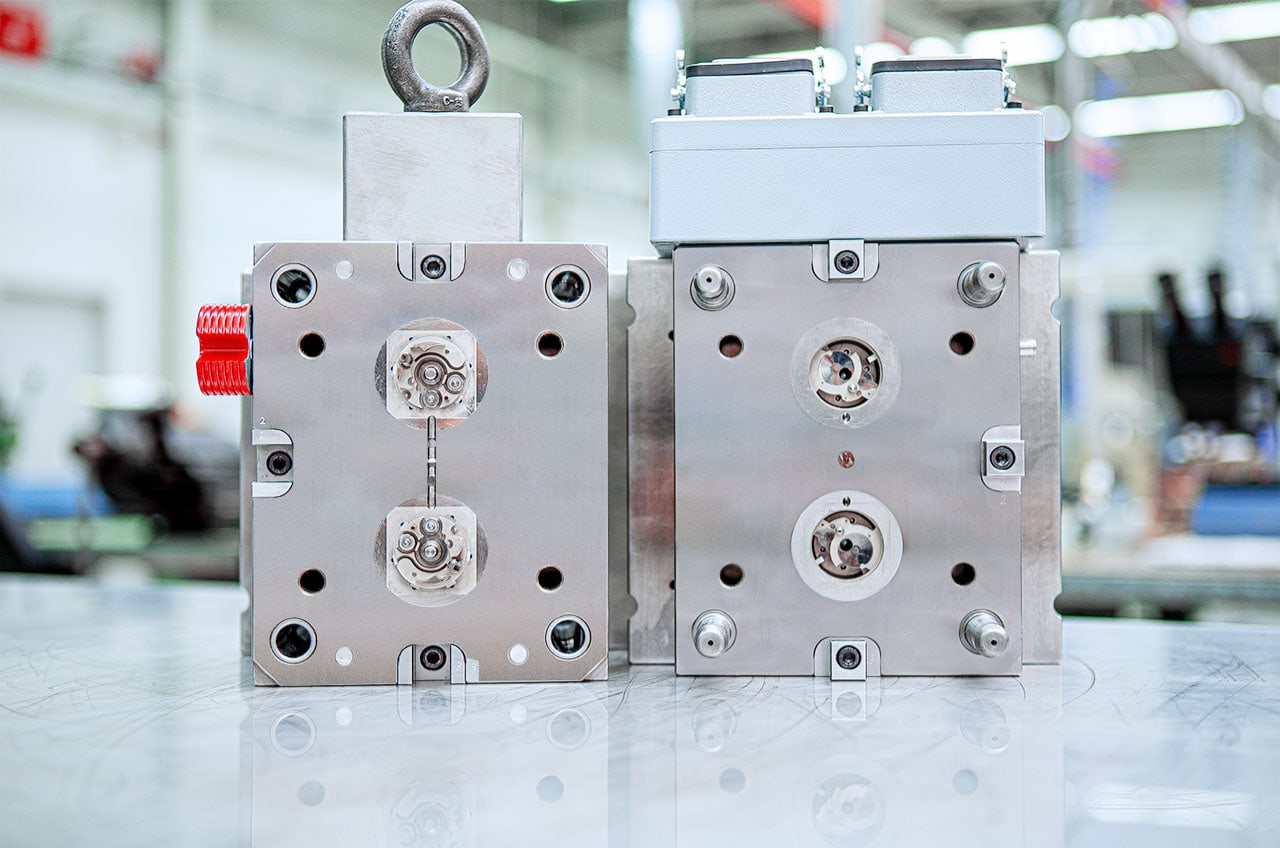

Top quality: functionality and sustainability under one roof

In order to ensure the precision required for fuze production as well as the fast availability of the necessary tools and moulds, we have our own tool and mould manufacturing department at the Dunningen-Seedorf site. 30 specialised employees develop and manufacture high-quality precision tools and injection moulds here, both for internal use and externally for customers in the automotive, avionics, medical and dental technology sectors. Beyond the technical aspect, any shortening of the supply chain contributes to sustainability, which we keep in mind with regard to all processes including our own environmental testing centre.

If you are interested in tool and mould construction in the civil sector, you can find further information on the specific dedicated website.

Network better –

your contact with us

Please contact us directly. We look forward to hearing from you. You can reach us by phone at +49 7402 181-0 or simply send an email to info@junghans-defence.com. Tip: it is best to visit our LinkedIn profile right away to connect directly with us.